Standards - Note 4

1.) Raceway Sizing

There are three options for sizing raceways according to 2017 PEC Table 10.1.1.1 [ or 2017 NEC Chapter 9 Table 1 ], based on cross-sectional areas:

A.) 53% raceway area for 1 conductor (a multiconductor cable is treated as a single conductor [Note 9])

B.) 31% raceway area for 2 conductors

C.) 40% raceway area for over 2 conductors

1.1.) Choosing Between Alternatives

For future expansion purposes, option (A) is far from practical. This may have use in very specific installations that are assumed to be not needing any expansions, but upgrades will definitely happen and option (A) will eventually become a bottleneck.

Option (B) for 2 conductors having a smaller area than either option (A) for 1 conductor or option (C) for over 2 conductors may seem nonsensical, but it actually does make sense. Having 2 conductors usually means 2 live wires supplying loads that may require an equipment grounding conductor (EGC) later on (3rd wire), or a neutral conductor to serve future center-tapped single-phase loads (4th wire). The new wires will eventually add up to the 40% area specified in option (C).

Option (C), therefore, provides the most flexible solution. Sizing raceways for a maximum of 5 wires (3 ungrounded, 1 neutral, 1 equipment grounding) can accommodate one of the following configurations:

* 1 single-conductor cable

* 1 multiconductor cable

* 2 single-conductor cables for 1-phase applications

* 3 single-conductor cables for 1-phase applications with EGC

* 3 single-conductor cables for 1-phase applications with center-tapped neutral

* 4 single-conductor cables for 1-phase applications with both center-tapped neutral and EGC

* 3 single-conductor cables for 3-phase delta applications

* 4 single-conductor cables for 3-phase delta applications with EGC

* 4 single-conductor cables (with 80% ampacity derating) for 3-phase wye applications with neutral

* 5 single-conductor cables (with 80% ampacity derating) for 3-phase wye applications with neutral and EGC

1.2.) Adjustment Factors

The 80% derating factor, located in 2017 PEC Table 3.10.2.6(B)(3)(a) [ or 2017 NEC Table 310.15(B)(3)(a) ], is applied to more than three current-carrying conductors inside raceways. This serves as an adjustment for their ampacities to ensure bigger conductors are selected by default, and avoid excessive heat that deteriorates insulation in narrow spaces.

1.3.) Selection Process

To select the adequate raceway size, it is important to keep in mind that the wire insulation also takes up space, so it must be considered as part of the wire cross-sectional area. The dimensions of insulated conductors can be found in 2017 PEC Table 10.1.1.5 [ or 2017 NEC Chapter 9 Table 5 ].

1.3.1.) After determining the insulation type and the conductor size in the said table, the approximate area of the wire cross-section is indicated in the next column.

1.3.2.) Multiply this approximate area by the number of conductors to be placed in the raceway, and this product represents the 40% raceway area to be filled.

1.3.3.) Cross-reference this product to the nearest adequate value under the 40% area column of PEC Table 10.1.1.4 [ or NEC Chapter 9 Table 4 ], and its equivalent raceway trade size is indicated in the leftmost column.

1.3.4.) Alternatively, the product in Step 1.3.2 can be divided by 0.4 (or 40%), and this quotient represents the 100% raceway area to be filled. Cross-reference this quotient under the 100% area column of PEC Table 10.1.1.4 [ or NEC Chapter 9 Table 4 ], and it will yield the same raceway trade size in Step 1.3.3.

The result of this selection process can be counter-checked using Tables C.1 to C.13 in 2017 PEC Appendix C [ or 2017 NEC Informative Annex C ].

It may be argued that PEC Appendix C [ or NEC Annex C ] can be applied directly instead of going through the steps outlined. However, the tables in PEC Appendix C [ or NEC Annex C ] only show the maximum number of conductors permitted for each raceway trade size, not the mathematical justification needed to ensure that the selected raceway has sufficient fill area.

It is recommended, therefore, that only veteran electrical practitioners use the tables in PEC Appendix C [ or NEC Annex C ]. Inexperienced electrical practitioners need to get familiar first with the math method of selecting raceways.

2.) Raceway Dimensions and Percent Area

Below are some handy tables pertaining to sizes of conduits and tubing that are commonly used as raceways.

These are derived from 2017 PEC Table 10.1.1.4 [ or 2017 NEC Chapter 9 Table 4 ], but are rearranged and trimmed to reduce complexity, as a product of the discussion on raceway sizing above.

2.1.) Electrical Metallic Tubing (EMT)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 15 | 0.50 | 15.8 | 0.62 | 196 | 0.30 | 78 | 0.12 |

| 20 | 0.75 | 20.9 | 0.82 | 343 | 0.53 | 137 | 0.21 |

| 25 | 1.00 | 26.6 | 1.05 | 556 | 0.86 | 222 | 0.34 |

| 32 | 1.25 | 35.1 | 1.38 | 968 | 1.50 | 387 | 0.60 |

| 40 | 1.50 | 40.9 | 1.61 | 1314 | 2.04 | 526 | 0.81 |

| 50 | 2.00 | 52.5 | 2.07 | 2165 | 3.36 | 866 | 1.34 |

| 65 | 2.50 | 69.4 | 2.73 | 3783 | 5.86 | 1513 | 2.35 |

| 80 | 3.00 | 85.2 | 3.35 | 5701 | 8.84 | 2280 | 3.53 |

| 90 | 3.50 | 97.4 | 3.83 | 7451 | 11.55 | 2980 | 4.62 |

| 100 | 4.00 | 110.1 | 4.33 | 9521 | 14.76 | 3808 | 5.90 |

-------------------------------------------------------------

2.2.) Electrical Nonmetallic Tubing (ENT)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 15 | 0.50 | 15.3 | 0.60 | 184 | 0.28 | 74 | 0.11 |

| 20 | 0.75 | 20.4 | 0.80 | 327 | 0.51 | 131 | 0.20 |

| 25 | 1.00 | 26.1 | 1.03 | 535 | 0.83 | 214 | 0.33 |

| 32 | 1.25 | 34.5 | 1.36 | 935 | 1.45 | 374 | 0.58 |

| 40 | 1.50 | 40.4 | 1.59 | 1282 | 1.99 | 513 | 0.79 |

| 50 | 2.00 | 52.0 | 2.05 | 2124 | 3.29 | 849 | 1.32 |

-------------------------------------------------------------

2.3.) Flexible Metal Conduit (FMC)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 10 | 0.38 | 9.7 | 0.38 | 74 | 0.11 | 30 | 0.05 |

| 15 | 0.50 | 16.1 | 0.63 | 204 | 0.32 | 81 | 0.13 |

| 20 | 0.75 | 20.9 | 0.82 | 343 | 0.53 | 137 | 0.21 |

| 25 | 1.00 | 25.9 | 1.02 | 527 | 0.82 | 211 | 0.33 |

| 32 | 1.25 | 32.4 | 1.28 | 824 | 1.28 | 330 | 0.51 |

| 40 | 1.50 | 39.1 | 1.54 | 1201 | 1.86 | 480 | 0.74 |

| 50 | 2.00 | 51.8 | 2.04 | 2107 | 3.27 | 843 | 1.31 |

| 65 | 2.50 | 63.5 | 2.50 | 3167 | 4.91 | 1267 | 1.96 |

| 80 | 3.00 | 76.2 | 3.00 | 4560 | 7.07 | 1824 | 2.83 |

| 90 | 3.50 | 88.9 | 3.50 | 6207 | 9.62 | 2483 | 3.85 |

| 100 | 4.00 | 101.6 | 4.00 | 8107 | 12.57 | 3243 | 5.03 |

-------------------------------------------------------------

2.4.) Intermediate Metal Conduit (IMC)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 15 | 0.50 | 16.8 | 0.66 | 222 | 0.34 | 89 | 0.14 |

| 20 | 0.75 | 21.9 | 0.86 | 377 | 0.58 | 151 | 0.23 |

| 25 | 1.00 | 28.1 | 1.11 | 620 | 0.96 | 248 | 0.38 |

| 32 | 1.25 | 36.8 | 1.45 | 1064 | 1.65 | 425 | 0.66 |

| 40 | 1.50 | 42.7 | 1.68 | 1432 | 2.22 | 573 | 0.89 |

| 50 | 2.00 | 54.6 | 2.15 | 2341 | 3.63 | 937 | 1.45 |

| 65 | 2.50 | 64.9 | 2.56 | 3308 | 5.13 | 1323 | 2.05 |

| 80 | 3.00 | 80.7 | 3.18 | 5115 | 7.93 | 2046 | 3.17 |

| 90 | 3.50 | 93.2 | 3.67 | 6822 | 10.57 | 2729 | 4.23 |

| 100 | 4.00 | 105.4 | 4.15 | 8725 | 13.52 | 3490 | 5.41 |

-------------------------------------------------------------

2.5.) Liquidtight Flexible Metal Conduit (LFMC)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 10 | 0.38 | 12.5 | 0.49 | 123 | 0.19 | 49 | 0.08 |

| 15 | 0.50 | 16.1 | 0.63 | 204 | 0.32 | 81 | 0.13 |

| 20 | 0.75 | 21.1 | 0.83 | 350 | 0.54 | 140 | 0.22 |

| 25 | 1.00 | 26.8 | 1.06 | 564 | 0.87 | 226 | 0.35 |

| 32 | 1.25 | 35.4 | 1.39 | 984 | 1.53 | 394 | 0.61 |

| 40 | 1.50 | 40.3 | 1.59 | 1276 | 1.98 | 510 | 0.79 |

| 50 | 2.00 | 51.6 | 2.03 | 2091 | 3.24 | 836 | 1.30 |

| 65 | 2.50 | 63.3 | 2.49 | 3147 | 4.88 | 1259 | 1.95 |

| 80 | 3.00 | 78.4 | 3.09 | 4827 | 7.48 | 1931 | 2.99 |

| 90 | 3.50 | 89.4 | 3.52 | 6277 | 9.73 | 2511 | 3.89 |

| 100 | 4.00 | 102.1 | 4.02 | 8187 | 12.69 | 3275 | 5.08 |

-------------------------------------------------------------

2.6.) Liquidtight Flexible Nonmetallic Conduit A (LFNC-A)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 10 | 0.38 | 12.6 | 0.50 | 125 | 0.19 | 50 | 0.08 |

| 15 | 0.50 | 16.0 | 0.63 | 201 | 0.31 | 80 | 0.12 |

| 20 | 0.75 | 21.0 | 0.83 | 346 | 0.54 | 139 | 0.21 |

| 25 | 1.00 | 26.5 | 1.04 | 552 | 0.85 | 221 | 0.34 |

| 32 | 1.25 | 35.1 | 1.38 | 968 | 1.50 | 387 | 0.60 |

| 40 | 1.50 | 40.7 | 1.60 | 1301 | 2.02 | 520 | 0.81 |

| 50 | 2.00 | 52.4 | 2.06 | 2157 | 3.34 | 863 | 1.34 |

-------------------------------------------------------------

2.7.) Liquidtight Flexible Nonmetallic Conduit B (LFNC-B)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 10 | 0.38 | 12.5 | 0.49 | 123 | 0.19 | 49 | 0.08 |

| 15 | 0.50 | 16.1 | 0.63 | 204 | 0.32 | 81 | 0.13 |

| 20 | 0.75 | 21.1 | 0.83 | 350 | 0.54 | 140 | 0.22 |

| 25 | 1.00 | 26.8 | 1.06 | 564 | 0.87 | 226 | 0.35 |

| 32 | 1.25 | 35.4 | 1.39 | 984 | 1.53 | 394 | 0.61 |

| 40 | 1.50 | 40.3 | 1.59 | 1276 | 1.98 | 510 | 0.79 |

| 50 | 2.00 | 51.6 | 2.03 | 2091 | 3.24 | 836 | 1.30 |

-------------------------------------------------------------

2.8.) Liquidtight Flexible Nonmetallic Conduit C (LFNC-C)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 10 | 0.38 | 12.3 | 0.48 | 119 | 0.18 | 48 | 0.07 |

| 15 | 0.50 | 15.7 | 0.62 | 194 | 0.30 | 77 | 0.12 |

| 20 | 0.75 | 20.7 | 0.81 | 337 | 0.52 | 135 | 0.21 |

| 25 | 1.00 | 26.2 | 1.03 | 539 | 0.84 | 216 | 0.33 |

| 32 | 1.25 | 34.8 | 1.37 | 951 | 1.47 | 380 | 0.59 |

| 40 | 1.50 | 40.3 | 1.59 | 1276 | 1.98 | 510 | 0.79 |

| 50 | 2.00 | 51.9 | 2.04 | 2116 | 3.28 | 846 | 1.31 |

-------------------------------------------------------------

2.9.) Rigid Metal Conduit (RMC)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 15 | 0.50 | 16.1 | 0.63 | 204 | 0.32 | 81 | 0.13 |

| 20 | 0.75 | 21.2 | 0.83 | 353 | 0.55 | 141 | 0.22 |

| 25 | 1.00 | 27.0 | 1.06 | 573 | 0.89 | 229 | 0.35 |

| 32 | 1.25 | 35.4 | 1.39 | 984 | 1.53 | 394 | 0.61 |

| 40 | 1.50 | 41.2 | 1.62 | 1333 | 2.07 | 533 | 0.83 |

| 50 | 2.00 | 52.9 | 2.08 | 2198 | 3.41 | 879 | 1.36 |

| 65 | 2.50 | 63.2 | 2.49 | 3137 | 4.86 | 1255 | 1.94 |

| 80 | 3.00 | 78.5 | 3.09 | 4840 | 7.50 | 1936 | 3.00 |

| 90 | 3.50 | 90.7 | 3.57 | 6461 | 10.01 | 2584 | 4.01 |

| 100 | 4.00 | 102.9 | 4.05 | 8316 | 12.89 | 3326 | 5.16 |

| 130 | 5.00 | 128.9 | 5.07 | 13050 | 20.23 | 5220 | 8.09 |

| 150 | 6.00 | 154.8 | 6.09 | 18821 | 29.17 | 7528 | 11.67 |

-------------------------------------------------------------

2.10.) Rigid PVC Schedule 40 and HDPE Conduit (PVC-40 and HDPE)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 15 | 0.50 | 15.3 | 0.60 | 184 | 0.28 | 74 | 0.11 |

| 20 | 0.75 | 20.4 | 0.80 | 327 | 0.51 | 131 | 0.20 |

| 25 | 1.00 | 26.1 | 1.03 | 535 | 0.83 | 214 | 0.33 |

| 32 | 1.25 | 34.5 | 1.36 | 935 | 1.45 | 374 | 0.58 |

| 40 | 1.50 | 40.1 | 1.58 | 1263 | 1.96 | 505 | 0.78 |

| 50 | 2.00 | 52.0 | 2.05 | 2124 | 3.29 | 849 | 1.32 |

| 65 | 2.50 | 62.1 | 2.44 | 3029 | 4.69 | 1212 | 1.88 |

| 80 | 3.00 | 77.3 | 3.04 | 4693 | 7.27 | 1877 | 2.91 |

| 90 | 3.50 | 89.4 | 3.52 | 6277 | 9.73 | 2511 | 3.89 |

| 100 | 4.00 | 101.5 | 4.00 | 8091 | 12.54 | 3237 | 5.02 |

| 130 | 5.00 | 127.4 | 5.02 | 12748 | 19.76 | 5099 | 7.90 |

| 150 | 6.00 | 153.2 | 6.03 | 18433 | 28.57 | 7373 | 11.43 |

-------------------------------------------------------------

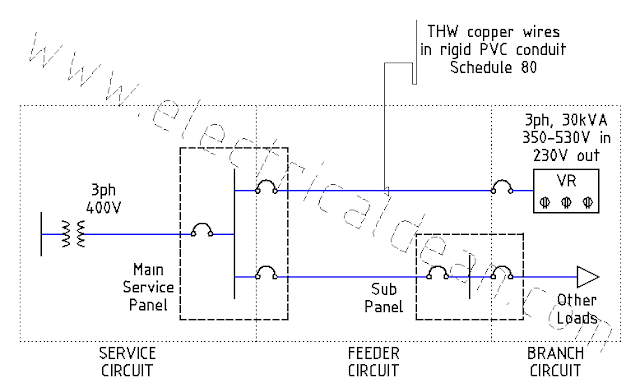

2.11.) Rigid PVC Schedule 80 Conduit (PVC-80)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 15 | 0.50 | 13.4 | 0.53 | 141 | 0.22 | 56 | 0.09 |

| 20 | 0.75 | 18.3 | 0.72 | 263 | 0.41 | 105 | 0.16 |

| 25 | 1.00 | 23.8 | 0.94 | 445 | 0.69 | 178 | 0.28 |

| 32 | 1.25 | 31.9 | 1.26 | 799 | 1.24 | 320 | 0.50 |

| 40 | 1.50 | 37.5 | 1.48 | 1104 | 1.71 | 442 | 0.68 |

| 50 | 2.00 | 48.6 | 1.91 | 1855 | 2.88 | 742 | 1.15 |

| 65 | 2.50 | 58.2 | 2.29 | 2660 | 4.12 | 1064 | 1.65 |

| 80 | 3.00 | 72.7 | 2.86 | 4151 | 6.43 | 1660 | 2.57 |

| 90 | 3.50 | 84.5 | 3.33 | 5608 | 8.69 | 2243 | 3.48 |

| 100 | 4.00 | 96.2 | 3.79 | 7268 | 11.27 | 2907 | 4.51 |

| 130 | 5.00 | 121.1 | 4.77 | 11518 | 17.85 | 4607 | 7.14 |

| 150 | 6.00 | 145.0 | 5.71 | 16513 | 25.60 | 6605 | 10.24 |

-------------------------------------------------------------

2.12.) Rigid PVC Conduit Type A (PVC-A)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 15 | 0.50 | 17.8 | 0.70 | 249 | 0.39 | 100 | 0.15 |

| 20 | 0.75 | 23.1 | 0.91 | 419 | 0.65 | 168 | 0.26 |

| 25 | 1.00 | 29.8 | 1.17 | 697 | 1.08 | 279 | 0.43 |

| 32 | 1.25 | 38.1 | 1.50 | 1140 | 1.77 | 456 | 0.71 |

| 40 | 1.50 | 43.7 | 1.72 | 1500 | 2.32 | 600 | 0.93 |

| 50 | 2.00 | 54.7 | 2.15 | 2350 | 3.64 | 940 | 1.46 |

| 65 | 2.50 | 66.9 | 2.63 | 3515 | 5.45 | 1406 | 2.18 |

| 80 | 3.00 | 82.0 | 3.23 | 5281 | 8.19 | 2112 | 3.27 |

| 90 | 3.50 | 93.7 | 3.69 | 6896 | 10.69 | 2758 | 4.28 |

| 100 | 4.00 | 106.2 | 4.18 | 8858 | 13.73 | 3543 | 5.49 |

-------------------------------------------------------------

2.13.) Rigid PVC Conduit Type EB (PVC-EB)

-------------------------------------------------------------

| Trade Size | Internal Dia. | 100% Area | 40% Area |

-------------------------------------------------------------

| mm | in. | mm | in. | mm^2 | in^2 | mm^2 | in^2 |

-------------------------------------------------------------

| 50 | 2.00 | 56.4 | 2.22 | 2498 | 3.87 | 999 | 1.55 |

| 80 | 3.00 | 84.6 | 3.33 | 5621 | 8.71 | 2248 | 3.49 |

| 90 | 3.50 | 96.6 | 3.80 | 7329 | 11.36 | 2932 | 4.54 |

| 100 | 4.00 | 108.9 | 4.29 | 9314 | 14.44 | 3726 | 5.77 |

| 130 | 5.00 | 135.0 | 5.31 | 14314 | 22.19 | 5726 | 8.87 |

| 150 | 6.00 | 160.9 | 6.33 | 20333 | 31.52 | 8133 | 12.61 |

-------------------------------------------------------------

==========

REFERENCES

1.) Philippine Electrical Code (SI Modernized Metric System)

1.1.) 2017 PEC Table 3.10.2.6(B)(3)(a) Adjustment Factors for More Than Three Current-Carrying Conductors.

1.2.) 2017 PEC Table 10.1.1.1 Percent of Cross Section of Conduit and Tubing for Conductors.

1.3.) 2017 PEC Table 10.1.1.1 Note 9 Multiconductor Cable as Single Conductor for Calculating Percentage Fill Area.

1.4.) 2017 PEC Table 10.1.1.4 Dimensions and Percent Area of Conduit and Tubing (Areas of Conduit or Tubing for the Combinations of Wires Permitted in Table 10.1.1.1).

1.5.) 2017 PEC Table 10.1.1.5 Dimensions of Insulated Conductors and Fixture Wires.

1.6.) 2017 PEC Appendix C Conduit and Tubing Fill Tables for Conductors and Fixture Wires of the Same Size.

2.) National Electrical Code (US Inch-Pound System)

2.1.) 2017 NEC Table 310.15(B)(3)(a) Adjustment Factors for More Than Three Current-Carrying Conductors.

2.2.) 2017 NEC Chapter 9 Table 1 Percent of Cross Section of Conduit and Tubing for Conductors.

2.3.) 2017 NEC Chapter 9 Table 1 Note 9 Multiconductor Cable as Single Conductor for Calculating Percentage Conduit or Tubing Fill Area.

2.4.) 2017 NEC Chapter 9 Table 4 Dimensions and Percent Area of Conduit and Tubing (Areas of Conduit or Tubing for the Combinations of Wires Permitted in Table 1, Chapter 9).

2.5.) 2017 NEC Chapter 9 Table 5 Dimensions of Insulated Conductors and Fixture Wires.

2.6.) 2017 NEC Informative Annex C Conduit and Tubing Fill Tables for Conductors and Fixture Wires of the Same Size.

Comments

Post a Comment